The paper tubes is also called as cardboard tubes, let's take a look at how they are made.

Manufacturing Process:

① Large pieces sheets of paper are cut into thin ribbons and an adhesive coating is applied to them.

② These ribbons are then winded on a mandrel and given a designated cylinder shape.

③ Cutting the cylinder shape tube into designated high.

④ Paste the surface paper (custom printing paper) on the cylinder shape tube

⑤ Rolled the edges of cylinder shape tube to make the edges curled (Rolled edge)

⑥ Assemble

⑦ Paper tube completed

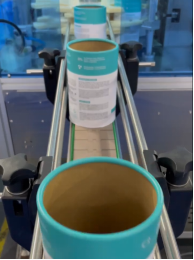

Custom Paper Tubes:

The size, color and brand logo can be customized according to customer requirements,

such as decorative foils, product information labels, various colors, patterns, and designs are also used.

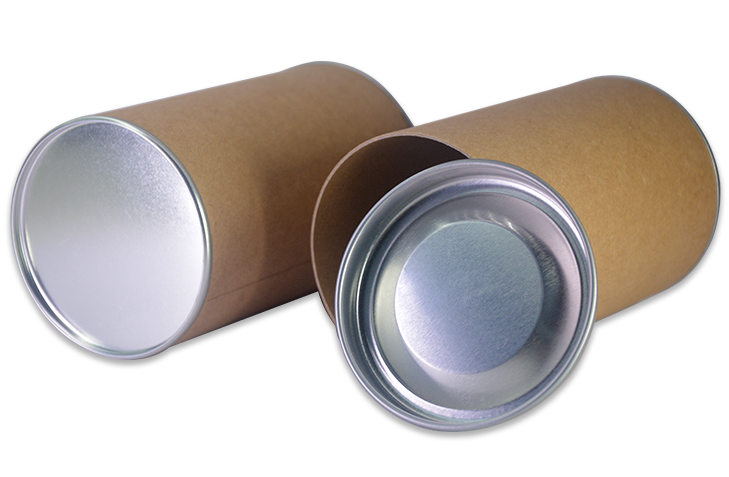

For the ends of the tubes, normally they are sealed with paper bottom.

But they can also be sealed with iron lid, easy-peel off lid and plastic lid, that can be used to seal the ends airtightly.

Contact: Hayley Lee

Phone: +86 132 2629 5712

E-mail: hayley@gzycpackaging.com

Whatsapp:+86 132 2629 5712

Add: NO. 13, Baoshu Road, Taihe Town, Baiyun District, Guangzhou City, Guangdong Province, China